Check our complete portfolio

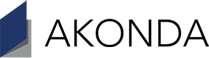

CalOne1000 – automate the process of wall calendars glueing!

Robustness verified on millions of calendars produced each year

More than 1000 calendars per hour

Made in Poland / EU

Flexible and efficient solution

Cal One 1000 is a revolutionary device automating the process of manufacturing glued wall calendars.

It can work with 1, 2, 3 or 4 pads with 12 tear-off sheets each or 1, 2, 3 pads and a head.

The mechanical speed of the machine is over 1,000 ready calendars per hour, with one device able to substitute 6 to 8 pairs of hands!

Automatic calendar backs feeder

The machine is equipped with a feeder with enough room for a stack of over 50 cm of calendar back.

The maximum length of a calendar back and a ready calendar is 100 cm. The calendar backs are picked by suction cups, and the strong blowers make sure that sheets – originating from both offset and digital printing operations – are separated from each other.

Calendar pads and head glueing

The calendar backs are aligned and then run in a stable manner through the entire machine.

The applied solutions ensure a high level of repeatability and the highest standards of quality of the end product.

Calendar pads and head feeder

The automatic feeder precisely separates pads from each other, preventing double feeds .

Calendar pads must be cut apart in advance into 12-month sets.

To ensure maximum manufacturing capacity, calendar pads may be added when the machine is in operation.

The calendar head is also automatically fed – hot melt glue is required.

Deliveries units

Depending on your preferences, Cal One may come with a stacker or with a belt at the outlet.

Stacker

Stacker has a 50cm capacity.

Belt

Belt can work in batch or stream mode.

Available configurations:

Glue*

Hot melt

(Preo Mini melter)

Water based

(pneumatic system)

Glueing stations*

3 calendar pads

4 calendar pads

3 calendar pads and head

only with hot-melt

4 calendar pads or 3 pads and a head (4th station exchangable)

only with hot-melt

(each opption can support 1 and 2 calendar pads)

Deliveries units*

Belt

Batch or stream mode

Stacker

With 50cm capacity

* Choose one, appropriate option for you

Technical parameters

| TECHNICAL PARAMETERS | ||

| Calendar gluing output – three-sectional | More than 1000 pcs / h | |

| Calendar gluing output – one-sectional | More than 1000 pcs / h | |

| Minimum cardboard width | 250 mm | |

| Maximum cardboard width | 330 mm | |

| Ready calendar (output) stacking unit capacity | 450 mm (~ 200 pcs) | |

| Cardboard unit capacity | 450 mm (~ 2,000 pcs; 230g cardboard) | |

| Minimum calendar block width | 250 mm | |

| Maximum calendar block width | 330 mm | |

| Dimensions | 1300 x 1850 x 3600 mm | |

| Power supply | 230V 50 Hz (400V with hot-melt melter) | |

Contact us for more infomations!

CAL-one mini

Semi-automatic calendards glueing.

More than 400 calendars per hour.

AKONDA – HQ

ul. Geodetów 176,

Piaseczno / Warszawa,

Poland

15 mins drive

from Warsaw Chopin Airport,

1 hour drive

from Warsaw Modlin Airport.

Production and test site

Bielsko-Biała,

Poland

1,5h drive

from Katowice-Pyrzowice Airport,

4h drive

from Warsaw, Bratislava, Vienna.